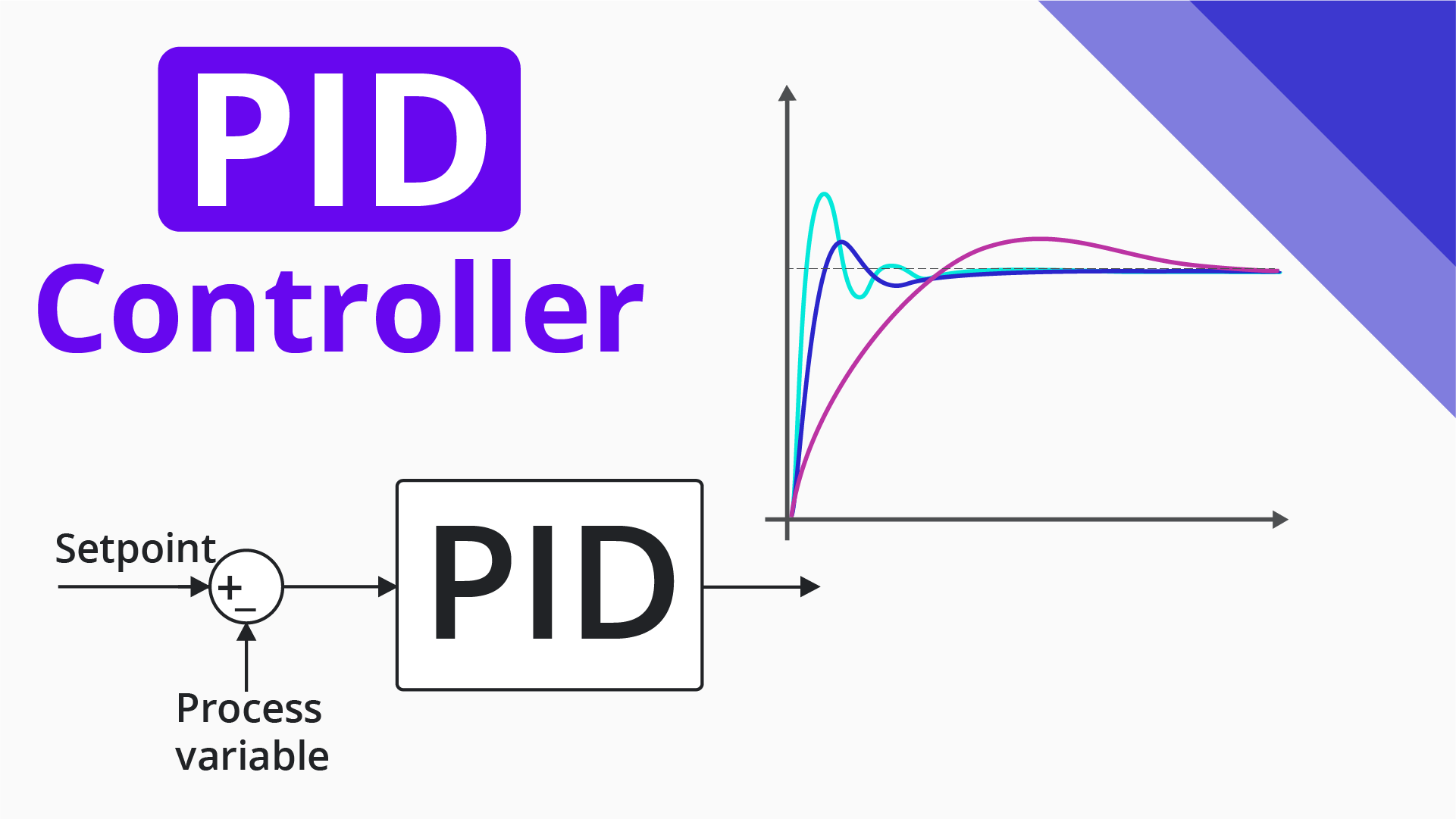

PID (Proportional-Integral-Derivative) control systems are powerful control methods used in industrial processes and automation applications to provide precise and stable control. These systems continuously measure process variables and automatically make adjustments based on these variables to reach the desired setpoints.

Basic PID Control Parameters:

Proportional (P): It makes a correction based on the instantaneous error (the difference between the desired value and the measured value). This allows the system to approach the desired value more quickly.

Integral (I): : Corrects accumulated error over time. It is used to reduce any steady-state error and increase system stability in the presence of continuous error.

Derivative (D): Responds to changes in the rate of change of the variable. It increases system stability against sudden changes by preventing overshoots.

Advantages of PID Control Systems:

Stable Control: PID control systems can adapt to continuously changing conditions and ensure system stability.

Precise Tuning: PID parameters can be adjusted according to control requirements, allowing for adaptation to various applications.

Fast Response: They provide rapid responses to instantaneous errors, enabling quick attainment of desired setpoints.

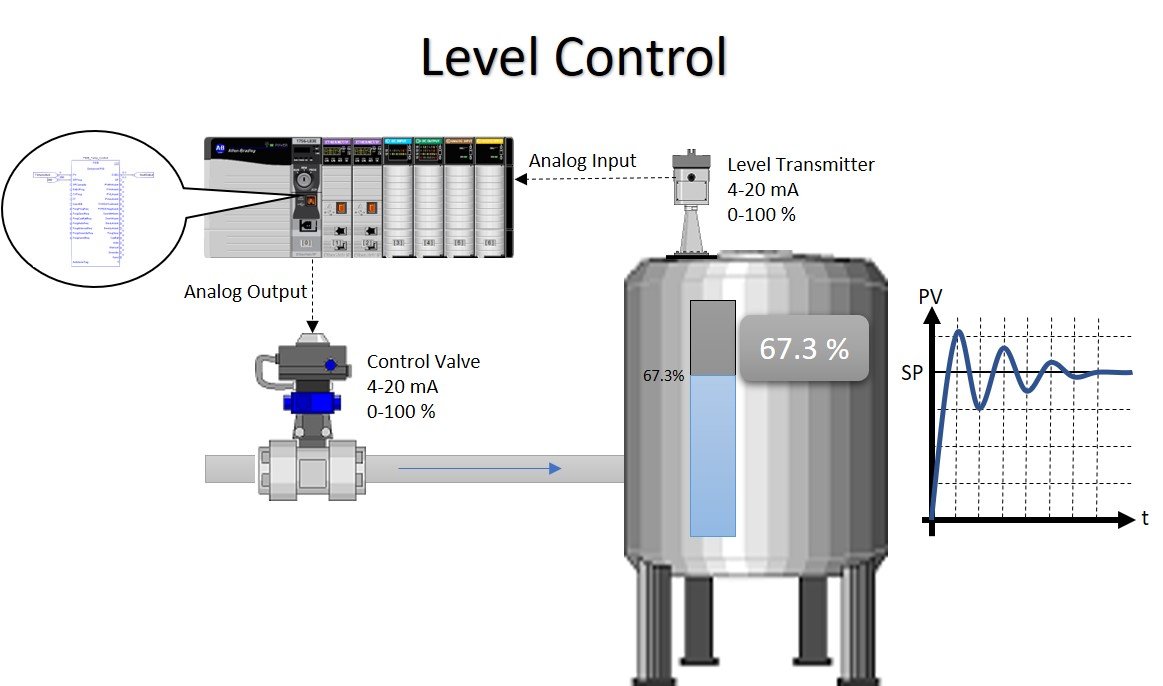

Diverse Applications: PID control systems are successfully used in many industrial applications, ranging from temperature control to motion control, water level regulation to pressure control.

Discover PID Control Systems with Us:

With our experienced team of engineers and leading position in the industry, we provide professional services for the design, installation, and integration of PID control systems. Contact us to optimize your processes and enhance efficiency with PID control systems tailored to your needs.

By doing so, you can achieve superior control in your industrial automation and manage your operations more effectively.